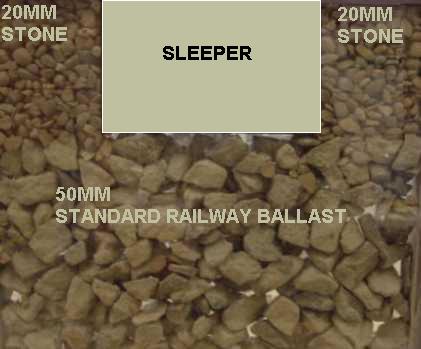

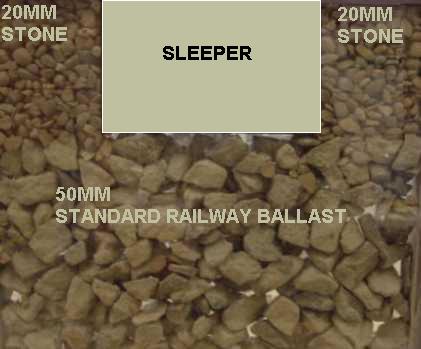

Figure 1.1 Section showing two layered ballast system

PROJECT BACKGROUND

The concept of two layered ballast system was proposed by Dr Michael Keedwell of Coventry University and patented by him. The system consists of replacing 50mm boxing ballast (crib ballast) around the sleepers with 20mm stone blowing stone as shown in figure 1.1

Figure 1.1 Section showing two layered ballast system

For durable track vertical geometry it is important that the ballast below the sleeper is left undisturbed after it has been compacted by traffic, a fact demonstrated by improved track top durability of track maintained using stone blowers. Thus a system is required which will fill up the voids below the sleepers before they become unacceptably large. With smaller size crib ballast when a void is formed under the sleeper larger than a certain size the smaller crib ballast rolls into the void maintaining sleeper vertical alignment.

Click here to see movie of the system

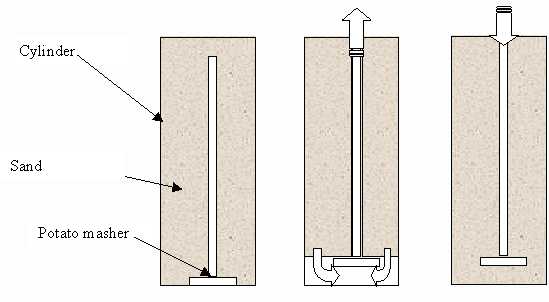

Dr Keedwell likened this idea to the potato masher principle as illustrated in figure 1.2. The potato masher placed in a cylinder filled with sand once lifted will not be able to move to its original position as the void below will be filled with sand.

Figure 1.2 The potato masher principle

The research at Coventry University, School of Science and Environment, funded

by Balfour Beatty and RMC concrete products is looking at practical application

of the system to railway track maintenance. Model tests and full scale tests

on the system have been carried out in the department laboratory.The tests have

shown that by replacing crib ballast by stone of smaller size a void beneath

the sleeper will be filled up to less than, the void size minus the average

particle size of crib ballast.

The next logical step is to go for full scale live track trials and it is anticipated

that these will take place in the near future.

more......